Intro

When you’re looking to make a new product, you’ll probably start with a prototyping phase. This includes creating physical versions of your product and trying them out. When it comes to prototyping, people typically choose between 3D printing and CNC machining.

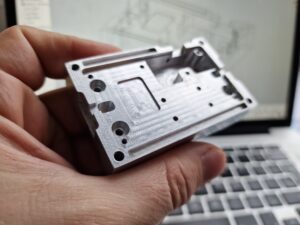

In a lot of cases, CNC-machined prototypes are the best option. Let’s discuss why that’s the case.

What Is CNC Machining?

Computerized Numerical Control (CNC) machining uses software and code to run a manufacturing machine. A common example is a CNC milling machine. The mill can be run by punching in numbers or loading a program from a computer.

The alternative to CNC is a manually operated machine that requires the machinist to spin dials and rotate arms to make the same cut.

With a CNC machine, a lot of the project can be automated. In our shop, we have cases where we load material and hit the “Go” button, and the CNC machine does the rest of the work.

Benefits of CNC-Machined Prototypes

A lot of people use CNC machining to make their prototypes, but why? Let’s discuss some of the major benefits of CNC-machined prototypes.

Tight Tolerances

With the right machine shop, you can hit very tight tolerances on your parts. This means that the prototype has a better chance of fitting into your assembly without any issues.

With tighter tolerances, you can take more chances during the design phase. Opening up the door for different prototype options is a quick way to improve your new product by testing the best-case design.

Great Quality

Quality is probably the biggest selling point when you CNC-machine your prototypes. You can make prototypes with 3D printers, but the finished quality isn’t as great. In addition, 3D printers can leave discrepancies across the part (due to the printing process), which hurts the final quality.

By default, CNC machines allow for a higher part quality.

With machining, you can also go through a series of finishing steps. These steps will add a polish, smooth out rough edges, and make the part look better. You can even powder coat or paint your prototype to make it look nicer.

Another quality-boosting benefit of CNC-machining your prototype is the ability to choose higher-quality material. Again, 3D printing falls short in this category.

Multiple Material Options

CNC machining opens the door to multiple different material options. You can create prototypes in plastic, metal, wood, and engineered materials. This means that your prototype will be more functional.

If the final product is going to be metal, it might not make sense to have a 3D-printed plastic part.

CNC machining offers the widest range of material types all with the same technology. With 3D printing, you’re limited — you’ll have to choose between a number of plastics or find a shop that has a metal 3D printer.

Similar to the Final Product

Using a CNC machine to create your prototype means that your part will act, look, and perform just like the final product. Of course, people typically use CNC machining to create the final production unit, so it makes sense to create a prototype using the same manufacturing method.

If you make a 3D-printed plastic prototype and then use a CNC machine to make the final part out of metal, your prototype isn’t as useful. If you have to run destructive tests or do a fitment check, then you could be wasting your time with a plastic prototype.

With a CNC-machined prototype, you’re getting the best results. If everything works well and you don’t change the design, there’s no need to make another CNC-machined part — your prototype becomes your final product.

Fast Turnarounds

CNC machining offers some impressive turnaround times. If your part is simple, then you could have it within a few days.

This is partially due to the hands-off nature of running a CNC machine. Once a machinist sets up the program, the rest of the process is pretty simple. When a shop can make parts faster and easier, then you can get parts quicker.

An experienced shop will have the right expertise and machines to get your parts to you even faster.

Conclusion

Now you know why CNC-machined prototypes are so great. CNC machining creates fast, versatile, strong, high-quality parts that are ready to be tested. The prototype will closely mirror the final product, so your tests will be more meaningful. At Rapid Axis, we can create production-quality CNC-machined prototypes at affordable rates and fast turnaround times. Get a free quote today to get started.